-

Standard: ISO9001:2015Number: 19822QK5750R0OIssue Date: 2022-11-15Expiry Date: 2025-11-14

-

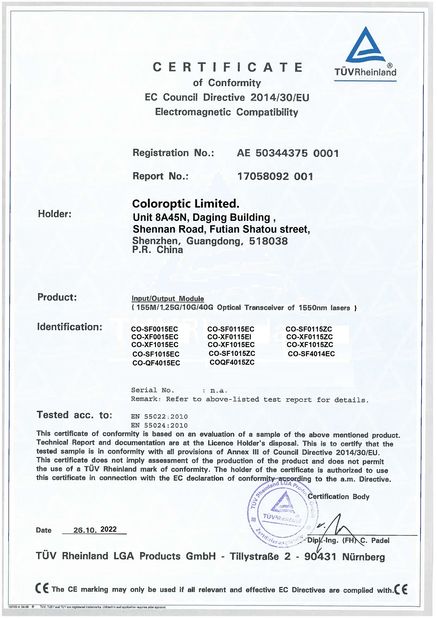

Standard: CENumber: AE503443750002Issue Date: 2022-10-16Expiry Date: 2025-11-20

-

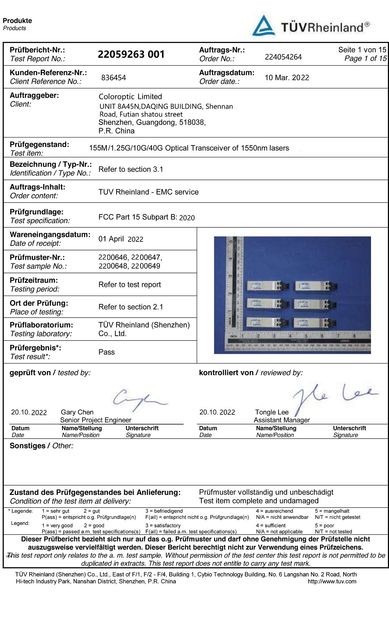

Standard: FCCNumber: 22059263Issue Date: 2022-10-20Expiry Date: 2026-02-25

-

Standard: ROHSNumber: BTS181212094004CCIssue Date: 2022-10-26Expiry Date: 2026-12-30

Quality Control Prifile

Quality control for mass production in an our factory:

1. Incoming Material Inspection:

- Thoroughly inspect all incoming materials, including optical components, electronic components, PCBs, and housing.

- Verify the quality, specifications, and compliance of each component with the approved standards.

- Conduct visual inspections and perform necessary tests to ensure proper functionality.

2. In-Process Quality Control:

- Implement regular inspections and tests at various stages of the manufacturing process.

- Monitor assembly procedures, soldering quality, and component placement accuracy.

- Conduct functional tests to ensure proper signal transmission, power consumption, and temperature control.

3. Final Product Testing:

- Perform comprehensive testing on finished optical transceivers.

- Conduct optical performance tests, such as signal integrity, sensitivity, and transmission distance.

- Verify electrical characteristics, including voltage levels, power consumption, and electromagnetic compatibility.

4. Reliability Testing:

- Subject a representative sample of the produced transceivers to rigorous reliability tests.

- Conduct environmental tests, including temperature cycling, humidity exposure, and vibration testing.

- Perform accelerated aging tests to ensure long-term reliability and durability.

5. Documentation and Traceability:

- Maintain detailed records of all inspections, tests, and measurements performed throughout the production process.

- Ensure proper traceability of components used in each unit of the transceivers.

- Document any deviations or non-conformities discovered during quality control processes.

6. Continuous Improvement:

- Regularly review quality control processes and identify areas for improvement.

- Implement corrective actions to address any identified issues or non-conformities.

- Foster a culture of continuous improvement to enhance overall product quality.

![]()