12 Cores Microduct Air-blown Single Mode Optical Fiber Cable

Product Details:

| Place of Origin: | China |

| Brand Name: | Sumitomo |

| Certification: | ROHS, CE, |

| Model Number: | GCYFY-12F |

Payment & Shipping Terms:

| Minimum Order Quantity: | 2 |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Cable drum |

| Delivery Time: | 8 DAYS |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 5000km / week |

|

Detail Information |

|||

| Cable Type: | Round/Ribbon | Nom. Diameter: | 4.8mm |

|---|---|---|---|

| Fiber Type: | Single Mode Type ITU-T G.652.D | Cable Sheath Marking: | JFOPT Neutral Printing Or Customized |

| Cable Bend: | 20 X Cable Dia. | Operate Temperature: | -10°C – +70°C |

| Storage Temperature: | -40℃~+85℃ | ||

| Highlight: | 12 Cores optical fiber Cable,Single Mode optical fiber Cable,Microduct optical fiber Cable |

||

Product Description

1. General

1.1 The specification covers the construction and properties of optical fiber cable.

1.2 It is designed to be quickly installed by blowing in micro-ducts.

1.3 The optical fiber which is used in the cable is also in compliance with ITU-T Rec. G.652.D.

1.4 The cable generally meets any latest relevant ITU-T Recommendation or better.

1.5 The single mode fiber shall operate in 1310nm and 1550nm.

1.6 The cable could serve for 25 years without any significant deterioration.

2. Optical Fiber in the Cable

2.1 Construction

| Fiber | Type | Single mode type ITU-T G.652.D |

| Material | Ge doped fused silica | |

|

Mode field diameter

|

1310 nm | 9.2±0.4 μm |

| 1550 nm | 10.4±0.8 μm | |

| Core concentricity error | ≤0.6μm | |

| Cladding diameter | 125±1μm | |

| Cladding non-circularity | ≤1.0% | |

| Coatting | Material | UV curable acrylate |

| diameter | 250±15μm(colored) | |

| Fiber proof-tested | 0.69 GPa ( 1.0%, 100kpsi) in accordance with the optical fiber proof test by IEC 60793-1-B1 | |

2.2 Optical characteristics

| Attenuation | 1310 nm | ≤ 0.36 dB/km | |

| 1550 nm | ≤ 0.22 dB/km | ||

| Zero-dispersion Wavelength | 1300~1324 nm | ||

| Zero-dispersion slope | ≤0.092ps/(nm2/km ) | ||

| Cable Cut-off Wavelength (λcc) | ≤ 1260nm | ||

|

Polarization Mode Dispersion(PMD)& PMDQ ( M=20,Q=0.01%) |

≤0.2 ps/km1/2 | ||

|

Macrobend Attenuation (10turns,Radius:30mm) |

1550 nm | ≤0.1 dB | |

| 1625 nm | ≤ 0.1dB | ||

3.Optical Cable

3.1 Construction

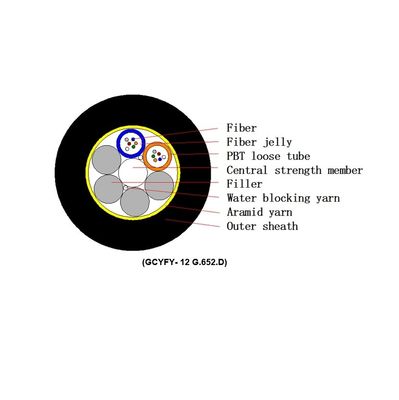

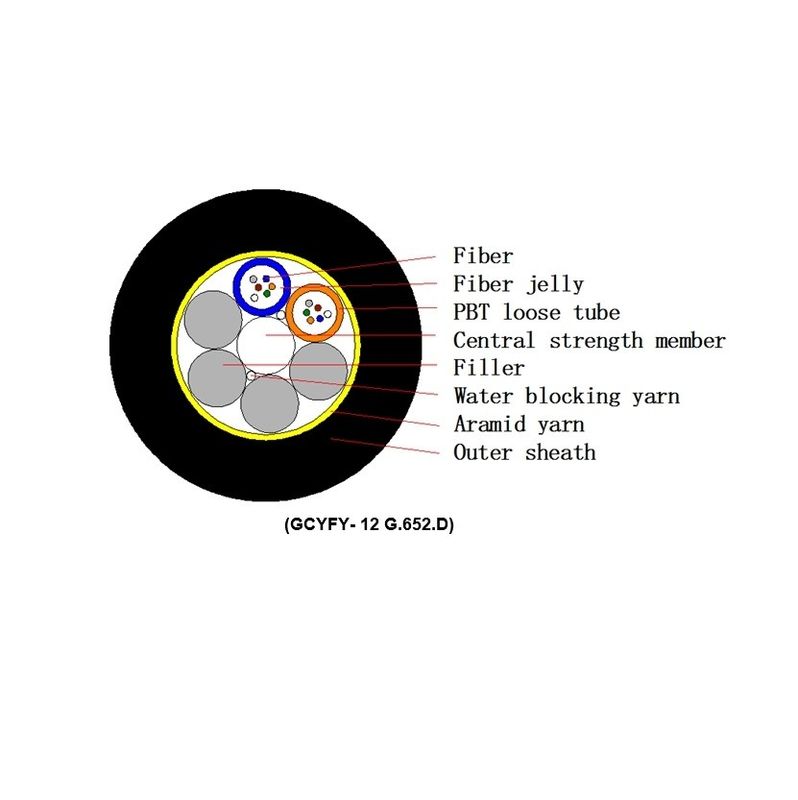

| Cable Type | GCYFY | |

| Fiber | Construction | Consult 3.1 |

| Central Strength Member | Material | FRP or FRP with PE coated |

| Tube | Material | PBT |

| Filling Compound Material | Fiber Jelly | |

| Filler | Material | PE |

| Water Blocking Member | Material | Water blocking yarn |

|

Addition Strength Member (If necessary) |

Material | Aramid yarn |

| Outer Sheath | Material | High density polyethylene colored black (With UV radiation protection) |

| Thickness | Nom. 0.4 mm | |

3.1.1 Buffer Tube Stranding, cable size and weight

|

Fiber count |

Fiber number per tube |

Number of tube / filler |

Nom. Diameter (mm) |

Approx weight (kg/km) |

| 6 | 6 | 1/5 | 4.8 | 20 |

| 12 | 6 | 2/4 | 4.8 | 20 |

| 24 | 6 | 4/2 | 4.8 | 20 |

| 36 | 6 | 6/0 | 4.8 | 20 |

| 48 | 8 | 6/0 | 5.1 | 20 |

| 60 | 12 | 5/1 | 5.7 | 30 |

| 72 | 12 | 6/0 | 5.7 | 30 |

| 84 | 12 | 7/0 | 6.1 | 35 |

| 96 | 12 | 8/0 | 6.5 | 40 |

| 144 | 12 | 12/0 | 8.1 | 55 |

3.2 Identification

Color Code for Fiber and Tube

| No. | 1 | 2 | 3 | 4 | 5 | 6 |

| Color | Blue | Orange | Green | Brown | Slate | White |

| No. | 7 | 8 | 9 | 10 | 11 | 12 |

| Color | Red | Black | Yellow | Violet | Rose | Aqua |

4. Optical Fiber Cable Characteristics

| Item | Test Condition | Specification at 1550nm |

|

Tensile Strength |

IEC 60794-1-2-E1 Load: 0.5G(G: Cable weight of 1km) Time: 10min |

Attenuation change ≤ 0.1 dB No damage on fiber and sheath |

|

Repeated Bending |

IEC 60794-1-2-E6 Bending radius: 20*cable dia. Load: 25N No. of cycle: 25 |

Attenuation change ≤ 0.1 dB No damage on fiber and sheath |

| Crush |

IEC 60794-1-2-E3 Max load: 450 N/100 mm Time: 1min |

Attenuation change ≤ 0.1 dB No damage on fiber and sheath |

| Twist |

IEC 60794-1-2-E7 Length: 1 m Load: 40N Angle: ± 180° No. of cycle: 5 |

Attenuation change ≤ 0.1 dB No damage on fiber and sheath |

| Cable Bend |

IEC 60794-1-2-E11 Mandrel Redius: 20 ´ Cable Dia. Turns: 10 No. of cycle: 5 |

Attenuation change £ 0.1 dB No defect on fiber and sheath |

| Drip test |

IEC-794-1-2-E14 Sample length: 30 cm Temp: 70°C Time: 24 hours |

No filling compound drip |

|

Temperature Cycling |

IEC 60794-1-2-F1 Temperature: -10°C – +70°C No. of cycle: 2 Duration time: 12hr/step |

Attenuation change ≤ 0.15 dB/km No damage on fiber and sheath |

| Water Penetration |

IEC 60794-1-2-F5B Time: 24 hours Sample length: 3M Water height: 1M |

No water leakage |

5. Cable sheath Marking

The length and identification marking are printed on the sheath at every one meter interval in white color. The accuracy of the length marking shall be ± 1.0 %. The contents of sheath marking shall be as follows:

- xxx: The name of manufacturer

- GCYFY: The type of cable

- **F : Fiber counts

- G.652D: The type of fiber

- 20**: The year of manufacture

- ****M: Length marking

※ The sheath marking can be changed with customer’s requirement.

6.Packing and shipping

6.1 Cable drum and drum Length.

The cable drum is wood drum. The diameter of the barrel shall not be less than 25 times the outside diameter of cable.

Standard drum length:4000m/drum (Or according to customer’s requirement)

7.2 The direction of rotation of the color scheme is shown by making the colokwise and anti-clockwise ends with red and green adhesive tape respectively